Metal spinning Metal spinning consists of a disk or cylinder of sheet metal that may be put on to a mandrel on a lathe plus a roller Instrument styles the sheet into the mandrel shape.

Have a company as sound as metal! There are a variety of wonderful marketplaces just waiting for a Metal Supermarkets retailer.

To prevent this, it’s imperative that you make certain that there are no other characteristics blocking the urgent by maintaining not less than two occasions the thickness of your sheet metal plus the bending radius obvious at the base on the sheet metal, as shown from the accompanying determine.

Do metal roofs provide Specific ventilation wants or condensation problems when mounted on properties? The general respond to is “no” but there's over a straightforward answer. Find out more about Metal Roofing and Air flow

As being the founder of MachineMFG, I have dedicated about a decade of my profession towards the metalworking sector. My considerable working experience has permitted me to become a specialist while in the fields of sheet metal fabrication, machining, mechanical engineering, and machine instruments for metals.

Our favourite reasonably priced cotton sheets are available in a person dimensions that may in shape a dorm bed, and they are available an assortment of solids and prints. Don’t wait to buy them, nevertheless—they market out rapid.

Under the exact device dimensions, the thicker the plate, the greater bending pressure is required. The bending force boosts as the plate thickness increases.

This is especially imperative that you remember if components that you are designing need to in shape into one another when assembled. The rule of thumb is to add half from the kerf towards the inner object and subtract the other 50 % of your kerf within the outer section.

Overall, these production procedures allow me to proficiently build a wide range of sheet metal items that cater to varied industries and purposes.

3D software package such as Solidworks, UG, Pro/E, SolidEdge, Topsolid, and CATIA have sheet metal elements and so are predominantly used to get facts demanded for sheet metal processing through the editing of 3D graphics.

Moreover, the spring back again of Japanese 301 stainless-steel is bigger than that of Taiwanese chrome steel.

Why here we like them: Amongst our favourite printed sheets, the Brooklinen Basic Core Sheet Established, comes in a rotating choice of contemporary prints. These sheets are made with a percale weave, a interesting, breathable form of cotton weave that feels mild and crisp against pores and skin. The sheets on their own are thinner (and lighter) than our top percale sheet decide from L.L.Bean, and so they really feel crisp and airy to slumber concerning. They’re Oeko-Tex Licensed, and they’re built with prolonged-staple cotton that gives them a clean truly feel and enough energy to endure many years of washing.

Building a bend having a spherical or larger sized hole accommodates a increased bending tolerance and makes sure correct assembly on the section.

This article appears in the sheet metal forming procedure, how it really works, where by it is made use of, and its Rewards and disadvantages. We also Check out the sub-processes accustomed to fabricate parts from your metal sheets.

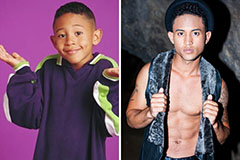

Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!